Oli K Pneumatic Linear Vibrator

Documentations

Application : Compacting, Matter conveying, Anit-bridging, Vibrating table

Matter : Dry - Low to medium density - Thin to medium Granulometry

Adapted to : Matter conglomerates in hoppers and pipes Fluidizing and Drain pans Matter conveying and dosage

Application sectors : Agri-food, Chemistry and Pharmaceutical, Various industries, Machines and installations

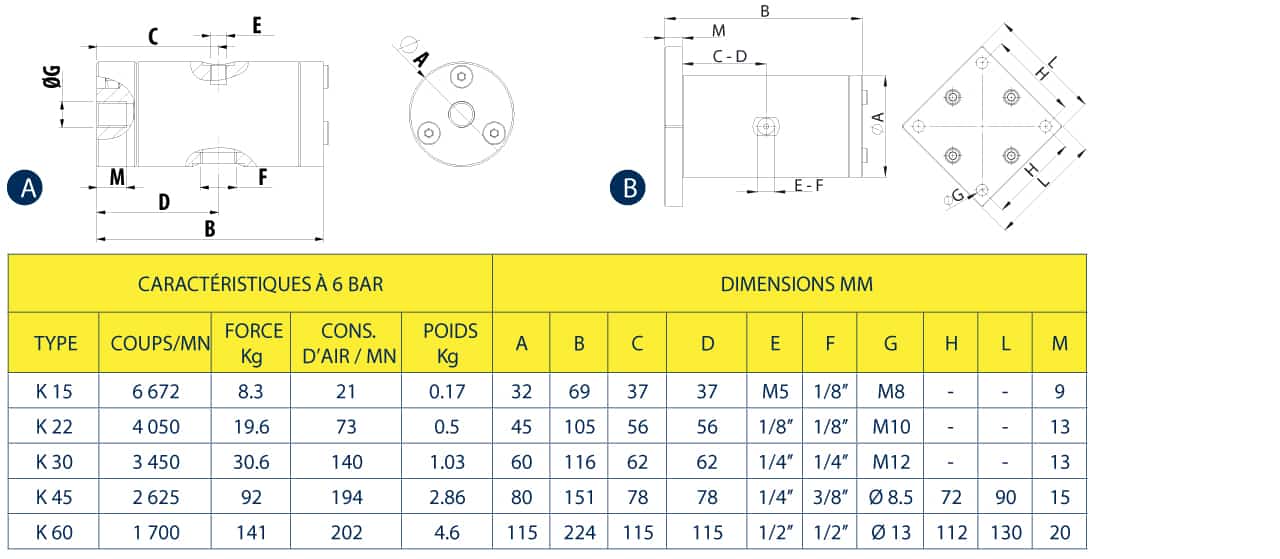

Centrifugal force : From 3.4 to 216 kg (adjustable Air pressure)

Frequency : 1260 V/min to 6720 V/min

Power supply : 2 to 6 BAR: Air compression, Oil mist filtering (“Lubrication free” range available)

Max. Operating temperature : -20°C to 130°C (-4 F to 266°F)

Materials : Aluminum body

Oli K Pneumatic Linear Vibrator

The Oli K Pneumatic Linear Vibrator line currently features over 5 models. Want to acquire or replace equipment? We will be happy to put our knowledge in service of all of your needs!

Contact us today to receive technical advice on your current projects. Our Oli K Pneumatic Linear Vibrators are in stock and ready to be shipped upon request.

To this day, Pneumatic Linear Vibrators offer a simple implementation solution, that facilitates the conveying and quantitative analysis of materials. Their piston floats freely between two air-cushions in order to generate a unidirectional vibration. They are easy to set up and to adjust, which will make it easy for you to integrate them to your plants.

Generally speaking, the Oli Pneumatic Linear Vibrator fits the needs of the following industries:

-

Agri-food

-

Chemistry and Pharmaceutical

-

Various industries

-

Machines and installations

This vibrator from the K-series has a maximum centrifugal force of 216 kgf (2.1 kN). Oli K Pneumatic Linear Vibrators combine multiple assets:

-

Instant ON/OFF power supply

-

Quiet operation, thanks to the absence of mechanical friction;

-

Compact, light and robust;

-

Number of vibrations per minute constantly adjustable though pressure adjustment;

-

Vibratory amplitude can be adjusted by reducing the flow of air that’s expelled.

-

No lubrication needed, made to work under high temperatures for specific models.

This is why those Oli K Pneumatic Linear Vibrators are an excellent alternative to electric vibrators, for any issues regarding materials conveying.

They can also be used in applications such as bulk powder compacting or hopper anti-bridging.

The pneumatic piston guarantees that the vibrations are perfectly linear, even in the event of higher frequencies and movements of high amplitude.

Besides, the stop brackets can occupy 1 or 4 holes, ensuring the best performances in every possible mounting position.

To top it up, as a guarantee of quality, our products are 100% manufactured in the EU.

Applicable standards and quality

This is why our vibrators conform with the most recent international and European Standards (EN) laws.

Moreover, the Oli pneumatic vibrator observes the most restrictive norms.

Directive: CE – Atex – Ex II 3 D.

In this regard, Vibraxtion pneumatic vibrating motors are adapted to applications in potentially flammable environments, zones 22 included. Check out our catalog now to find out what Oli K Pneumatic Linear Vibrator best fits your needs.

To this day, Oli vibrating motors have become a world benchmark among industrialists thanks to their attractive prices and industrial quality.

The Vibraxtion expertise

Whatever your feasibility study is, Vibraxtion is committed to helping you and giving you full satisfaction.

-

Vibraxtion is above all the preferred partner for integrators in charge of the strictest industrial applications.

-

Besides, Vibraxtion makes it possible for distributors to find Vibraxtion products that will fit the standards set by their customers.

-

And finally, Vibraxtion provides all users with its expertise in industrial vibrators to best address their needs.

Contact our experts now to find out what vibrating motor best suits your application and your needs in industrial equipments.

Ref Oli Pneumatic Vibrator: K 15 (1 hole) – K 22 (1 hole) – K 30 (1 hole) – K 45 (4 holes) – K 60 (4 holes)