Oli U025 U060 Sweeper Nozzles, for airing powdered bulk matter

Documentation

Power supply : 0.2 to 1 BAR: Air compression, continuously filtered

Max. Operating temperature : -20°C to +80°C (-4 F to 176°F)

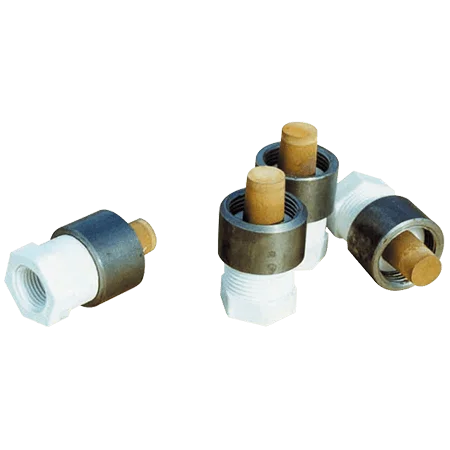

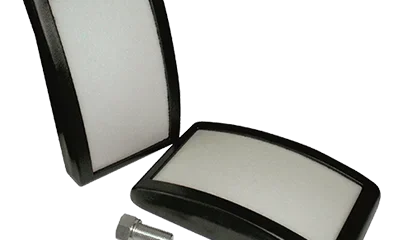

OLI Sweeper Nozzles Range: U025 U060

Oli Sweeper Nozzles from the U025 and U060 range keep dry bulk materials in motion. They can be mounted directly on the outside of the device. As a result, they are particularly adapted to bins that usually cannot be accessed from the inside for modernization purposes.

OLI Sweeper Nozzles carry out a constantly regular flow of your powdered bulk products. Thanks the ventilation and vibration on the hopper’s side, any blockage is thus hindered: This dual action actually prevents the formation of bridges, agglomerates and compact pockets.

Indeed, sweeper nozzles decompact the product, thus allowing a better flow. In this way, the nozzle forces the air to circulate between the inner sides, thus cleaning the device by detaching stuck matter. Moreover, when in contact with a surface, sweeper nozzles guarantee a complete airtightness, which prevents any blockage.

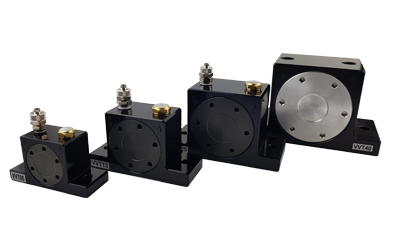

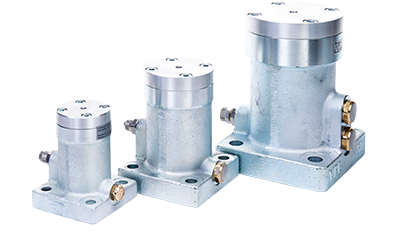

In this way, they allow a regular flow of dry powdered products for all your hoppers, and flat or conical silos. However, please note that the installation must be of a neutral PH, and of a temperature below 80 C (176 F). Besides, sweeper nozzles only work with products of low moisture content. Highly coarse matter such as gravel, sand, cereals or foodstuff for cattle should not be ventilated. If granulates interlocking with one another are moist, the use of sweeper nozzles is not recommended. In this case, we advise to use Turbine Vibrators or Impact Vibrators.

Check out our catalog now to find out what OLI Sweeper Nozzle (U025 and U060) best fits your applications. Contact us today to get more information and inquire about brand new devices or a device replacement. Our experts will be happy to help!

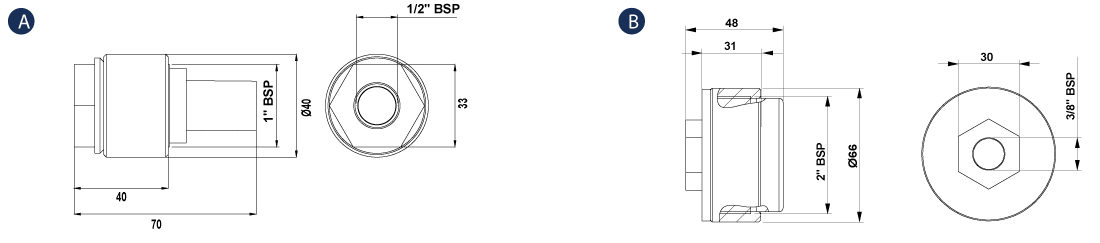

| TYPE | CONSOMMATION D’AIR | ||||

|---|---|---|---|---|---|

| Modèle | Fig. | 0,2 Bar (2,9 psi) | 1 Bar (14 psi) | ||

| l/min | Cfm | l/min | Cfm | ||

| U025 | A | 0,83 | 0,03 | – | – |

| U060 | B | – | – | 30 | 1,1 |