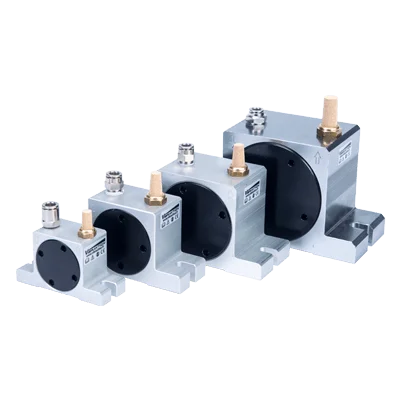

Oli OT Pneumatic Turbine Vibrator

Documentations

Maintenance

Application : Compacting, Anit-bridging, Concrete and plastic compacting, Vibrating table, Conveying of matter an parts

Matter : Dry or humid- Low to medium density - Thin to medium Granulometry

Adapted to : Vibratory applications that do not require lubricating

Application sectors : Agri-food, Buildings and construction works, Chemistry and Pharmaceutical, Various industries

Centrifugal force : From 72 to 1718 kg (adjustable Air pressure)

Frequency : 6000 V/min to 42,000 V/min

Power supply : 2 to 6 BAR : Air compression (No lubrication)

Max. Operating temperature : -20°C to 120°C (-4 F to 248°F)

Materials : Aluminum body

Oli OT Pneumatic Turbine Vibrator

The Oli OT Pneumatic Turbine Vibrator line currently features over 12 models. Want to acquire or replace equipment? We will be happy to put our knowledge in service of all of your needs!

Contact us today to receive technical advice on your current projects. Our Oli OT Pneumatic Turbine Vibrators are in stock and ready to be shipped upon request.

To this day, pneumatic turbine vibrators are the most universal type of rotative pneumatic vibrators. Thanks to their top-quality and lifelong lubricated roller bearings, they will never require maintenance. And because there is no lubricant in the compressed air network, they can be used in any industry sector.

Generally speaking, the Oli Pneumatic Turbine Vibrator fits the needs of the following industries:

-

Agri-food

-

Building and construction

-

Chemistry and Pharmaceutical

-

Energy and environment

-

Foundry and heavy industry

-

Machines and installations

This vibrator from the OT series has a maximum centrifugal force of 1718 kgf (16.85 kN).

Oli OT Pneumatic Turbine Vibrators combine multiple assets:

-

Quiet operation, thanks to the absence of mechanical friction;

-

Compact, light and robust;

-

Very modular adjustments and installations

-

No lubrication needed, made to work under high temperatures.

This is why those Oli OT Turbine Vibrators are an excellent alternative to electric vibrators, for any issues regarding the flow of your hoppers, silos and pipeworks.

They can also be used in the concrete industry to compact matter inside molds:

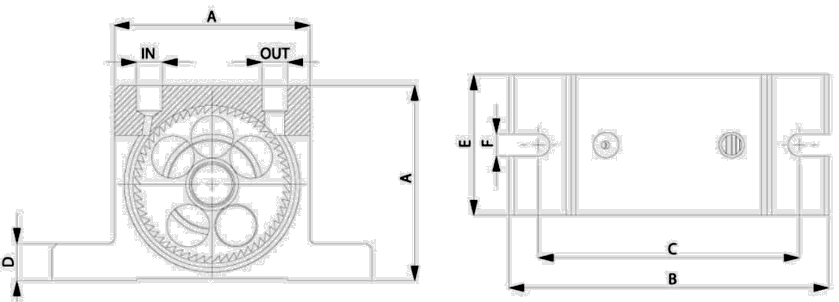

the specific profile of the shovel-shaped turbine produces high frequencies, as well as wide movements.

The top-quality groove bearings of the Oli OT Pneumatic Vibrators grant you the best performances in every possible mounting position.

To top it up, as a guarantee of quality, our products are 100% manufactured in the EU.

Applicable standards and quality

This is why our vibrators conform with the most recent international and European Standards (EN) laws.

Moreover, the Oli pneumatic vibrator observes the most restrictive norms.

Directive: CE – Atex – Ex II 2 GD.

In this regard, Oli pneumatic vibrating motors are adapted to applications in potentially flammable environments, zones 21 / 22 included. Check out our catalog now to find out what Oli OT Pneumatic Turbine Vibrator best fits your needs.

To this day, Oli vibrating motors have become a world benchmark among industrialists thanks to their attractive prices and industrial quality.

The Vibraxtion expertise

Whatever your feasibility study is, Vibraxtion is committed to helping you and giving you full satisfaction.

-

Vibraxtion is above all the preferred partner for integrators in charge of the strictest industrial applications.

-

Besides, Vibraxtion makes it possible for distributors to find Vibraxtion products that will fit the standards set by their customers.

-

And finally, Vibraxtion provides all users with its expertise in industrial vibrators to best address their needs.

Contact our experts now to find out what vibrating motor best suits your application and your needs in industrial equipments.

Ref Oli Pneumatic Vibrator: OT 8 – OT 10 – OT 10S – OT 13 – OT 16 – OT 16S – OT 20 – OT 25 – OT 25S – OT 30 – OT 36 – OT 36S