Concrete can be vibrated during the finishing state in order to optimize its quality.

The vibration eliminates the remaining air pockets, as well as the water and laitance left in the concrete.

What role does the vibration play?

When applied to fresh concrete, the vibration usually favors the arrangement of the grains concrete is composed of. This process has a dual role:

-

easier set up for molds-filling and reinforcements covering;

-

the resulting concrete has a stronger density, and fewer air pockets (clamping effect).

Using this technique makes it possible to produce concrete with less mixing water: its porosity is diminished while its mechanical properties are enhanced, thus improving its durability and overall aspect.

Vibrating concrete: features and effects

Vibrating fresh concrete

-

Amélioration de la maniabilité

The vibration enhances the viscosity of the concrete. This is why it is highly recommended to reduce the quantity of mixing water (e.g. by using admixture), since a large part will not be used for cement moisturizing and will only contribute to plasticizing the concrete.

With the adapted vibration, you will be able to efficiently make use of a stiff, water-poor concrete that, once hardened, will have very low porosity. -

Expulsion de l’air

The reduction of the friction force (concrete liquefaction) makes gravity forces predominant. Compared to its surrounding environment, air density is very low. Air will thus be subject to a strong buoyancy force, that tends to attract it back towards the surface.

That phenomenon can be clearly observed when the vibration is ongoing. When the air flow stops, the vibration has no effect on the clamping of concrete anymore. This is a critical issue that can bring about a segregation of the granulates, which are heavier than cement’s laitance.

By contrast, when vibrating excessively, there is a risk that lighter granulates are forced up to the surface.

Vibrating hardened concrete

Once hardened, vibrated fresh concrete possesses the following enhanced features:

-

low porosity, induced by the cumulative effects of clamping, vacuuming and the reduction of mixing water (intended to guarantee the malleability of the concrete);

-

better homogeneity, thanks to a vibration that is transmitted to the entirety of the mass;

-

efficient covering of the frameworks.

Vibrating concrete according to specific parameters

-

Énergie

The energy transmitted by the vibrator is proportional to the mass of the rotating eccentric weight, to its eccentricity, and to the square of its speed. The energy characterizes the efficiency of a device: it must be as high as possible, and remain compatible with the size of the vibrator.

-

Fréquence

The optimal frequency varies depending on the size of the granulates. A low frequency (approx. 10.000 vib./min) boosts the vibration of big granulates, while a high frequency (approx. 20.000 vib./min) boosts the vibration of thinner elements.

-

Amplitude

This factor determines, more particularly, the movement of the components inside the concrete during half a vibration. Measuring it, tough, is delicate.

We can however consider that too high an amplitude favors segregation, especially in the case of soft concrete. This is why it is wiser to limit it and favor the increase in frequency. -

Durée

The duration of a vibration is important in so that, if too short, the concrete will not be compact enough; if too long, it may provoke the segregation of its components.

The effects of a vibration in a set time are characterized by a quick action, that reduces very fast once the grains are laid out and the air is expelled.For reference, the periods required for vibrating a volume of concrete (by pervibration, i.e. the moment where the poker stays in the same position) are of:-

5 seconds for soft concrete,

-

20 seconds for plastic concrete,

-

1 minute for stiff concrete.

-

Vibratory equipment

There are two main categories of vibratory equipment:

-

those that produce a vibration that is internal to the concrete (i.e. pervibration), where the vibrator directly affects the concrete from the inside;

-

those that produce an external vibration, that is when the concrete is vibrated through a casing or a beam.

Internal vibrators

These simple yet effective vibrators are often used on site. Sometimes called “vibrating pokers”, they are made of a metal tube, in which an offset eccentric weight rotates to produce vibrations.

-

Energie

Several forms of energy are used for various applications: pneumatic, electric, thermal.

The diameter for a standard poker ranges from 25 to 100 mm. Their frequency ranges from 10.000 to 20.000 vib./min. -

Aiguilles

A poker must be chosen according to its mass. It makes it more or less maneuverable, and guarantees that its diameter is compatible with the spacing between the frames, so that it can easily be positioned. Besides, the other main criteria for choosing a poker are the volume of concrete you want to vibrate, and its granulometry.

Pokers ranging from 25 to 70 mm are usually used for volumes of concrete that do not exceed 10 m3, with the diameter of the biggest granulates measuring less than 25 mm.

Pokers longer than 70 mm are usually used for volumes of concrete ranging from 10 to 20 m3, with a high granulometry.

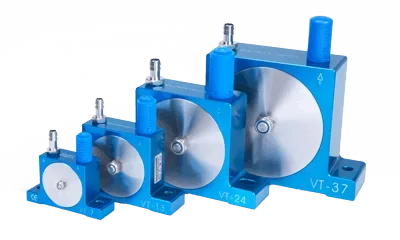

External vibrators

A more detailed approach to vibrating tables is available in our publication about prefabrication. Casing vibrators and vibrating screeds are used on construction sites.

-

Les vibreurs de coffrages

Just like pokers, casing vibrators work thanks to an offset eccentric weight that rotates to produce a vibration. Vibrators are attached to a casing, and must be heavy and stiff enough to transmit a homogeneous vibration without getting deformed.

The vibration frequency of electric vibrators often ranges from 3.000 to 6.000 vib./min. Pneumatic vibrators can reach higher frequencies, that range from 10.000 to 15.000 vib./min. Since the depth of the concrete concerned by the vibration generally does not exceed 20 to 25 cm, this type of vibrator is more adapted to elements of average thickness: wall, sails, poles, beams.

-

Les vibreurs de béton de surface

Vibrating screeds can transmit the vibration from a ruler or a beam laid on the concrete’s surface.

The vibrator is fixed to the ruler. The latter must be of a sufficient inertia and stiffness.

This type of vibration is restricted to slabs, roads made of concrete and, generally speaking, to any horizontal element of a small thickness (max. 15 to 20 cm).

Vibrate concrete efficiently

Best practice rules are mainly related to the duration of the vibration, their frequencies and the positioning of the vibrator.

The duration of the vibration is linked to the nature of the concrete (granulometry, consistency), the volume there is to vibrate, the density of the metallic framework. It also varies according to the type of vibrators and their power.

Thanks to some hints, we can assess the moment when the vibration should be interrupted:

-

the concrete does not compress anymore;

-

there are no more air bubbles;

-

laitance appears on the surface.

Internal vibration

Using vibrating pokers requires a few precautions:

-

do not vibrate successive layers over 40 to 50 cm thick and, at all events, of a thickness smaller than the length of the vibrating poker in use;

-

sink the poker into the subjacent layer 10 cm into the concrete;

-

let the poker sink under its own weight and, when it emerges from the concrete, let the cavity close by itself;

-

avoid getting too close to the framework and the casing, in order to avoid any heterogeneous sidings;

-

shift the poker every 30 to 50 cm (i.e. about 1,5x its range) if your needle is of a standard diameter (ranging from 50 to 75 mm).

External vibration

It is harder to determine where the vibrators should be installed and how long the vibration should last because of numerous factors: the nature of the mold or the casing, the shape of the element, the volume of concrete, and its composition. To get the best possible result, experience, preliminary tests and an assistance from the vibrators’ manufacturer often are a necessity.

Vibrating concrete evenly

Vibration is an efficient way to set up concrete. Vibrating concrete allows to limit the amount of water it would usually need, and to increase its final characteristics by decreasing its porosity.

To obtain a good-quality concrete, you must first use a proper blend. Then, you must adapt the vibration to the composition of the concrete and to the application you need it for. Feel free to contact us! We are here to help you find the vibratory equipment that best suits your application needs.

Finally, you need to make sure that the vibration applies evenly to the whole volume of concrete. Otherwise, you may create heterogeneities that would not only be detrimental to the porosity and the coating of the frameworks, but also deteriorate the appearance of the siding.