Vibramotors, the only manufacturer of electric micro vibrators in stainless steel body

Vibramotors is the result of a long internal development of our French company Vibraxtion in order to meet the requirements of our customers and industrial partners:

3 Reasons to choose Vibramotors

Combined expertise in special machines and motorization

The Vibramotors motors have been developed in order to integrate perfectly with our realizations of special machines and our vibrating tables.

We are thus able to provide you with equipment entirely produced by us for a perfectly controlled integration.

This global expertise in vibrating application is the assurance of full satisfaction for all your projects.

Optimized compatibility

To date, Vibramotors has become a worldwide benchmark for versatility and quality in the industrial sector.

This is why Vibramotors offers a complete range of vibrators compatible with all major brands for customers wishing to optimize their installations at a lower cost.

Compliance with the most demanding standards

The Vibramotors Electric Vibrators are designed to observe the highest performance, even under the most demanding applications.

As a rule and according to the new international directives, all Vibraxtion Electric Vibrators comply with the ATEX IEC EN 61241-0 et 61241-1 standards.

In this regard, each motor is certified and can be used safely in dusty and potentially flammable environments (ATX II 2 D Certification).

The Vibramotors vibrators range

-

Electric Micro Vibrators steel or stainless steel body

This range of electric vibrator is probably the most relevant for small vibrating applications. Indeed, thanks to their small sizes, the AMV & AMVSS Vibramotors Electric Micro Vibrators fit easily into your extremely compact applications.

- AMVSS Stainless Steel Micro Vibrators are the only micro-vibrators with casings and external components made of 316L stainless steel on the entire market. They are the result of in-house development to meet the demand for food, pharmaceutical or corrosive environment applications.

- AMV Micro Vibrators offer an alternative to pneumatic vibrators for all your problems with bridges and chimneys in small hoppers.

-

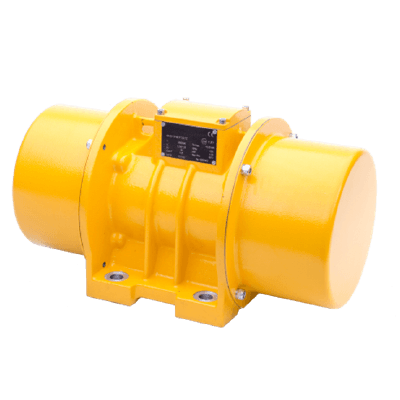

Electric Industrial Vibrators

- Our MV Electric Vibrators can be used for all kinds of vibrating equipment in all industrial fields. Indeed, they provide compaction, fluidification, flow assistance, guidance or transport.

-

Pneumatic Rotative Vibrators

Rotary vibrators generate vibrations with reduced amplitude and high frequency.

-

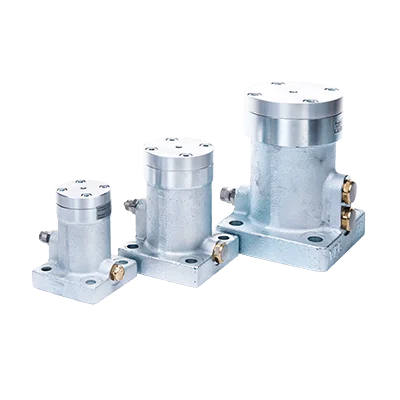

Pneumatic Linear Vibrators

- PVL Linear Pneumatic Vibrators offer an easy-to-implement and effective solution for material conveying and dosing. Their piston floats freely between two air cushions to generate a unidirectional vibration. Their fineness of adjustment and their ease of assembly allow easy integration into your installations..

-

Pneumatic Impact Vibrator

- Pneumatic Impact Vibrator PVP offer an easy-to-implement and effective solution for detaching by hammering the materials causing deposits on your hopper walls, particularly in wet areas. Continuous high-frequency striking makes it possible to obtain the effect of a “mallet blow” combined with a vibratory frequency specifically adapted to the type of difficult materials.

-

Multi-Center-to-Center Stiffeners for Pneumatic Vibrators

Other Vibraxtion products and accessories

Vibraxtion also offers its clients and industrial distributors a wide and complete selection of

Vibraxtion also offers its clients and industrial distributors a wide and complete selection of