Oli I 100 Fluidizing Plate – Bulk Powdered Materials Aeration

Documentation

Power supply : 0.2 to 1 BAR: Air compression, continuously filtered

Max. Operating temperature : -20°C to +80°C (-4 F to 176°F)

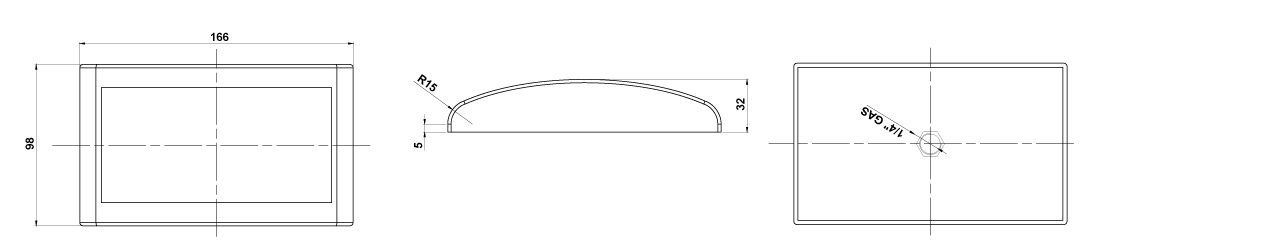

Oli I 100 Fluidizing Plate – Type: I 100

The Oli I 100 Fluidizing Plate allows a preventive fluidization of your powdered bulk materials.

Thanks to its shape and porous membrane, the air propagates efficiently against the walls of your silos: your silo is treated in its entirety. The quantity and position of fluidizing plates vary according the dimensions of your silo.

The fluidizing process can be used preventively. For an optimal flow of the stored products, numerous fluidizing techniques exist. For example, matter can be fluidized by injecting the proper air quantity at regular intervals. OLI I 100 Fluidizing Plates offer a great flexibility (moderate pressure of 0.2 BAR). Indeed, not only does this technique prevent the creation of bridges and hourglass-shaped conglomerates, but it also keeps the matter or material in motion. This way, during long term storage phases, an I 100 Fluidizing Plate prevents compacting and, consequently, draining issues.

The OLI I 100 Fluidizing Plate is suitable for dry products with a fine grain texture, e.g cement, lime, calcium carbonate. This way, products can be aerated with low air consumption. (0.12 M3 / hour).

Please note: Fluidizing plates are not adapted to all products or environments:

For foodstuff installations, we recommend using bin aerators from the VBS range, that are equipped with a membrane adapted to foodstuff. For moist products (>3%), we recommend using external pneumatic vibrators or, Alternatively, you can use Knockers should your products have specific characteristics that require a direct action on the hopper.

In this regard, please contact our specialists for any inquiry that does not concern product replacement.

Feel free to check our catalog to find out what I 100 Fluidizing Plate best suits your needs. You can also contact us now to receive more detailed explanations or to inquire about brand new devices or a device replacement. Our experts will be happy to help!