OLI is a subsidiary of WAMGROUP, world leader in terms of development and production of equipment for the bulk handling sectors.

Oli Offers The Most Versatile Equipments

To this day, Oli has become a world benchmark of the industry sector thanks to their attractive prices and industrial quality.

-

This is why Oli vibrating motors offer the widest range of vibrators on the market for machinery manufacturers and vibratory set-ups.

-

As a rule and according to the new international directives, all Oli electric vibrators comply with the ATEX IEC EN 61241-0 et 61241-1.

-

In this regard, each motor is certified and can be used safely in dusty and potentially flammable environments (ATX II 2 D Certification).

The Oli Vibrators range

Oli Electric Micro Vibrator

- The MVE MICRO range is the perfect application solution for reduced spaces and/or dimensions.

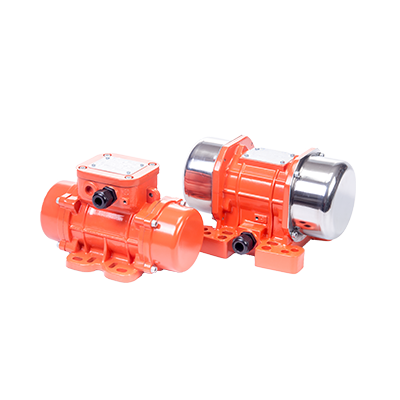

Oli Industrial Electric Vibrators

“MVE” models can reach a centrifugal force value of up to 26,000 kgf (260 kN).

Oli Rotative Pneumatic Vibrators

Rotative vibrators generate high-frequency, reduced-amplitude vibrations.

- The vibrations produced by the “S” Ball Vibrators are generated by the movement of balls inside a cage.

- The vibrations produced by Roller Bearings Vibrators are generated by the movement of rollers inside a cage. In this regard, devices from the “OR” range generate a higher force than Ball Vibrators from the “S” range.

- The vibrations produced by the Pneumatic Turbine Vibrators from the “OT” range are generated by a turbine with eccentric weights. The “OT” range features high-performance equipment, in so far as this model is faster than ball and roller bearings vibrators.

Vibrateurs Pneumatiques Linéaires Oli

- The linear vibrations produced by Vibrators from the “K” range are generated by the movement of an internal floating piston, rather than by direct contact between surfaces. This is why this kind of vibrator is also called “Piston Vibrator”.

Oli Pneumatic Impact Vibrator

- Pneumatic Impact Vibrators from the “P” range produce shock waves. These are generated by the continuous impact of the internal piston on a welded metal base frame, on either the inner sides of the hopper or at its bottom.

- “PS” Electropneumatic Impact Vibrators are particularly adapted to the modernization of hoppers/cone bottom silos. They should function intermittently, under a pressure of 3 to 6 BAR (44 ~ 87 PSI).

Oli Air fluidizer

- Oli Bin Aerators from the VBS-VBSM range can preventively flux bulk powdered matter and materials. This way, thanks to its convex shape, the air spreads effectively.

- U025 and U060 Sweeper Nozzles are the most economical solution to ensure a regular flow of matter in silos, bottoms or hoppers.

- I100 Fluidizing plates are mounted in a special, light, yet robust polymer casing, with an ingenious filter system. They are widely used in single-line installations, for cement and other similar materials.

Contact Vibraxtion for your inquiries on Oli products

Contact us today to receive technical advice on your current projects. Our Vibraxtion products are in stock and ready to be shipped upon request!